Although I’ve never been a fan of Cybis’ Hall of Fame series of replicated “legacy” sculptures, I’ve always been curious about how they managed to produce identical but downscaled versions of pieces whose original molds were supposedly destroyed decades ago. So, I decided to learn how the upsize/downsize process actually works.

In my quest to find out how re-scaling of such objects is done, I spoke with Dan Mehlman of Mehlman Design in upstate New York. He has been a mold-maker and designer of beautiful objects in ceramics, glass and metal for more almost 40 years and explained the processes by which a perfectly-rescaled porcelain sculpture can be produced; I’m extremely grateful to him for his help!

Downsizing

The classic centuries-old process of downsizing any ceramic object produced from a mold utilizes an inherent characteristic of the material itself, which is the fact that it shrinks during the firing process. But why does that happen? It’s because every ceramic starts its life as a mixture of dry and wet ingredients that are combined to form a paste (clay), and the liquid ingredient is water. When exposed to the high heat of a kiln, the water begins to evaporate and this leaves microscopic ‘holes’ where the water used to be; the tiny particles of clay move into these minute openings created by the vaporized water. By the time the firing process is completed, all of those tiny solid particles are compressed very tightly together….and the actual volume of the molded piece has now changed, because you have removed (through vaporization) some of the original material, i.e. the water. And with altered volume comes altered dimensions: in other words, shrinkage.

The percentage of shrinkage depends upon the type of clay (the actual ingredients, which also determine the size of all those tiny solid particles) being used. For instance, earthenware clay typically shrinks only about 6% to 8% while stoneware articles have an average shrinkage rate of about 10% or so. Porcelain – because the solid particles are extremely fine and tiny – has the highest shrinkage rate of any ceramic: anywhere from 13% to 20% depending in large part on the exact “mix” of ingredients being used, the firing temperature, etc.

This shrinkage characteristic provides a simple way to make smaller copies of an existing piece. It’s not necessary to have the original mold; all that’s needed is one finished sculpture. Let’s say it’s the original Lady Macbeth from the 1970s. We take one of these original sculptures and we create a new mold from it. Then we fill that new mold with the porcelain clay mixture and fire it. When we remove the fired piece from the kiln, it is going to be smaller than when it went in. How much smaller will depend on the shrinkage rate; likewise, we can figure out the shrinkage rate by comparing the finished (fired) sizes of the original and the newly-made pieces. But the resulting piece will always be smaller than the piece that the new mold was made from. Let’s continue with our Lady MacBeth example:

The original Lady Macbeth is ‘officially’ 13″ high which in reality means anything between 13″ and 13.24″ in height. If the Cybis formula’s shrinkage rate is 13%, that would downsize a 13”-high new mold by about 1.69” – resulting in a height of 11.33” for a resulting downsized piece. Likewise, if their shrinkage rate is 14%, the resulting piece would be just a tad over 11” (11.18” in fact). Unfortunately the Cybis website never gave the details of the first Hall-of-Fame (HOF) Lady Macbeth (which they named Lady Macbeth II) so we don’t know her official height … but by extrapolating this method, we can guess that she was 11″ tall.

Cybis subsequently produced a second HOF piece named Lady Macbeth III. For this edition they would have repeated the process described above, but this time would have made the new mold from a finished Lady Macbeth II. Applying a 14% shrinkage rate to this starting point (an 11″ mold) would result in a sculpture that is 9.68” tall; a 13% shrinkage rate would produce a 9.86” tall piece. The Cybis website cites Lady Macbeth III as being 10” tall which means she’s anywhere from 9.75” to 10” in reality. The math works perfectly! The effective result is that with every downsizing at their typical shrinkage rate, a Cybis sculpture will be reduced in height by between one and two inches. Theoretically Cybis could have continued making downsized Lady Macbeth replica editions in 8″ high (“IV”) and 6″ high (“V”) versions (but thank goodness they did not.)

Now I will stand upon my soapbox for just a moment to explain why I so dislike the HOF concept. I “get” the logic that these are (technically speaking) not identical to the vintage original pieces, because they are (a) smaller in size and (b) may be somewhat different in decorative details (but not always). However, the fact remains that although the original vintage molds were not used to produce the HOF pieces directly, the original vintage piece was used. They are not “new sculptures”, although they were indeed “new retail items”. The dictionary definition of ‘replica’ is

a copy or reproduction, especially one on a scale smaller than the original.

Clearly, the Cybis Hall of Fame editions are copies. They are reproductions. They are replicas. I would have preferred, from a collector point of view, that Cybis would instead have created a truly new HOF series described as being “inspired by” or “based on” the originals. In other words, entirely new designs that would be similar to the originals but not replicas. However, that would have been far more expensive than the process that I have described. But it also would not have been an affront to collectors who had bought the original editions and believed the studio’s original claim that those designs would “never be produced again.” That promise was broken with the creation of the HOF series. Okay, end of rant.

Upsizing

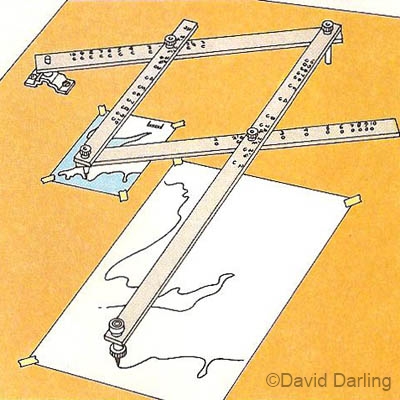

Because the process described above will only work when making a sculpture smaller, how then is a piece upscaled in dimension? This process does require specialized equipment known as a 3D pantograph, which is a type of ‘pointing machine’. A pointing machine is typically used for making exact copies, and you may have even used one yourself; it can be as simple as something made from four pieces of wood or metal that is used for copying diagrams or drawings. These are often called drafting pantographs:

But when dealing with a three-dimensional object the pantograph necessarily has to be more complex in order to “copy” from all sides. The photo below is from sculptor Michael Keropian’s website in which he explains and illustrates how these machines work. As you can see, they sometimes need to be quite large!

However, when dealing with pieces on the scale of Cybis porcelains which are typically less than 24″ tall, equipment as large as the one above is not needed.

Mr. Keropian explains very clearly and concisely how a 3D pantograph works:

The pantograph is basically a boom or arm with two pointers. Both pointers move together. While one pointer of the pantograph traces the surface of a sculpture model, the other point follows the pattern in space allowing the sculptor to determine the surface body of the enlarged sculpture. The boom sits on a pivot mechanism or ball and a counter weight allows the boom to float. This helps the sculptor trace the surface of the model.

Cybis could have arranged for someone with such a pantograph to produce a single upsized version of an original, and then cast their own mold from the resulting larger sculpture…but I have never found even one instance of upsizing being done by Cybis.

3D Computer Re-Scaling

Of course, nowadays there is the option of using 3D computer modelling but that technology is relatively new; it certainly wouldn’t have been available in 1990 which is when Cybis introduced their Hall of Fame concept. Even when it eventually becomes cost-effective, the process isn’t 100% optimal for this purpose. This is because essentially it is a combination of photography and scanning: a camera element using a laser captures dimensionally-plotted images of an object from multiple angles and then merges them together, rather like creating a panoramic photograph by digitally stitching the individual shots together end to end. However, unlike butting the straight flat ends of photographs together, when working in three dimensions there is some inevitable ‘overlay’ which can muddy the perfect accuracy of the scan; and certain surfaces, especially reflective or dark areas, can also bounce the laser beam backwards before it does its data-recording job. Both situations will result in slight irregularities in the finished product as compared to the original. In any case, investing in such equipment just for the very occasional up- or down-scaled production run wouldn’t be practical for an art porcelain studio; it’d be serious overkill.

Any copying process – whether 1:1 or upsizing or downsizing – will still require a certain level of finishing work, just as the normal process of producing a porcelain sculpture does. The piece needs to be “cleaned up”, the details sharpened, and any separate decorative elements added. All of this adds to the artistic value of the piece and contributes to its individual uniqueness. The Star Trek “replicator” technology isn’t quite here yet…and in the case of art objects, I think that’s a good thing! :-)

Name Index of Cybis Sculptures

Visual Index (for human figures/busts only)

About the Cybis Reference Archive

What is Cybis?

Images of Cybis porcelain sculptures are provided for informational and educational purposes only. All photographs are copyrighted by their owner as indicated via watermark. Please see the copyright notice in the footer and sidebar for important information regarding the text that appears within this website.

The Cybis Archive provides the most comprehensive range of information about Cybis within a single source. It is not and never has been part of the Cybis Porcelain studio, which is no longer in business.